-

This community needs YOUR help today. With the ever increasing fees of everything (server, software, domain, e-mail) , we need help. We need more Supporting Members, today. Please invest back into this community to help spread our love and knowledge of IH Cub Cadets. You get a lot of great new account perks including access to private forums. If you sign up for annual, I will ship a few IH Cub Cadet Forum decals too in addition to all the account perks you get. You can see what it looks like below.

Sign up here: https://www.ihcubcadet.com/account/upgrades

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Archive through November 18, 2008

- Thread starter kide

- Start date

Help Support IH Cub Cadet Tractor Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

rchristensen

Well-known member

- Joined

- Aug 12, 2006

- Messages

- 933

- displayname

- Richard Christensen

Brad You could have a weak coil and you do need a fully charged battery.

On these old Cubs the thing I look for is bad wires or connections. The wire from the coil to the points is often the problem due to the heat it gets brittle and can break inside of the insulation or the insulation can wear off and cause a intermittent short when it touches metal.

The best way to test a coil is substitute a known good one as they can give different symptoms.

If I suspect carburetor problems I usually give them a shot of carburetor cleaner and about everything will run if you shoot carb cleaner in it.

Stay with it and you will figure it out.

On these old Cubs the thing I look for is bad wires or connections. The wire from the coil to the points is often the problem due to the heat it gets brittle and can break inside of the insulation or the insulation can wear off and cause a intermittent short when it touches metal.

The best way to test a coil is substitute a known good one as they can give different symptoms.

If I suspect carburetor problems I usually give them a shot of carburetor cleaner and about everything will run if you shoot carb cleaner in it.

Stay with it and you will figure it out.

Brad R,

On 4 cycle engines, the coil should fire the plug on every second revolution (i.e. every other turn) near the top of the compression stroke. Sounds like you may have a bad spark plug or coil. Also carefully inspect the wire from the points to the coil for any signs of cracked insulation/broken wires. Sometimes the insulation on those wires gets hard and cracks which can cause it to ground out intermittantly. Also with the points cover off, spark plug removed and switch off, rotate the engine to close the points. Then with the plug grounded to the frame and connected to the coil, turn the switch on and manually open the points several times by hand. Each time you open the points, the coil and plug should fire. If they don't, then try a new plug and plug wire. If that don't fix it, then try a new or used coil that is known to work. One other thing to check is the new points. Sometimes oxides can build up on the contact surfaces if they have set on the shelf a long time and subjected to humidity and you have to run a thin, flat file between them several times to clean the oxides off.

Also on the carb settings, the service manual settings are just a place to start. You may have to open then more then the suggested 3 1/2 turns to get the the engine to run correctly.

On 4 cycle engines, the coil should fire the plug on every second revolution (i.e. every other turn) near the top of the compression stroke. Sounds like you may have a bad spark plug or coil. Also carefully inspect the wire from the points to the coil for any signs of cracked insulation/broken wires. Sometimes the insulation on those wires gets hard and cracks which can cause it to ground out intermittantly. Also with the points cover off, spark plug removed and switch off, rotate the engine to close the points. Then with the plug grounded to the frame and connected to the coil, turn the switch on and manually open the points several times by hand. Each time you open the points, the coil and plug should fire. If they don't, then try a new plug and plug wire. If that don't fix it, then try a new or used coil that is known to work. One other thing to check is the new points. Sometimes oxides can build up on the contact surfaces if they have set on the shelf a long time and subjected to humidity and you have to run a thin, flat file between them several times to clean the oxides off.

Also on the carb settings, the service manual settings are just a place to start. You may have to open then more then the suggested 3 1/2 turns to get the the engine to run correctly.

Took the spare hydro apart today.and have a couple questions.

In the hydro FAQS K McGiver stated when you drive the pins out of the trunion shaft be real careful not to drive them to far.He also refered to the manual,which I have,but nowhere does it state how far to drive them out,it just says drive them out!!SO,

#1 how far do I drive them out and what am I to look out for?driveing them into the case?

He also stated He had a method, that is not mentioned,to drive the pins out thats not so tedious.

#2 do any of you know the method?

(I found a post from him and cant get no info to email him,maybe not a member still??)

He also stated to work clean,I did my best!,what do you reccomend I clean everything with?

The two pins in question are on the left and right of the picture,sorry no way to make a pointer.

In the hydro FAQS K McGiver stated when you drive the pins out of the trunion shaft be real careful not to drive them to far.He also refered to the manual,which I have,but nowhere does it state how far to drive them out,it just says drive them out!!SO,

#1 how far do I drive them out and what am I to look out for?driveing them into the case?

He also stated He had a method, that is not mentioned,to drive the pins out thats not so tedious.

#2 do any of you know the method?

(I found a post from him and cant get no info to email him,maybe not a member still??)

He also stated to work clean,I did my best!,what do you reccomend I clean everything with?

The two pins in question are on the left and right of the picture,sorry no way to make a pointer.

Hello All,

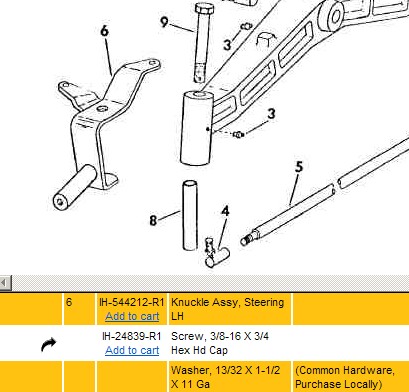

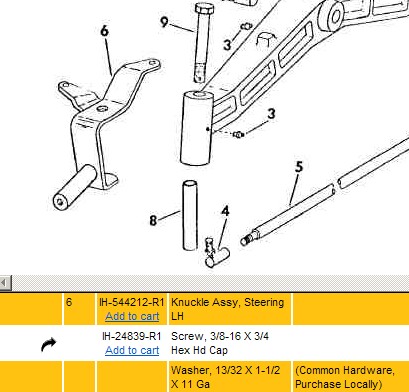

Anyone know the part numbers for both the washer and bolt used to hold the front wheels on the spindles of a 149. Tried to find those parts on Cub Cadet Parts Lookup but no luck. Thanks for the info.

Kenneth

Anyone know the part numbers for both the washer and bolt used to hold the front wheels on the spindles of a 149. Tried to find those parts on Cub Cadet Parts Lookup but no luck. Thanks for the info.

Kenneth

Jason D,

It depends whether or not you have a early hydro pump or later hydro pump. Early hydro pumps did not have the hole for the roll pins going through the back side of the squash plate control and only have a single roll pin on each trunnion shaft. If you drive the roll pin in too far it will bottom out in the squash plate hole for the trunnion and make it difficult to remove the trunnion shafts due to the pin contacting the hole. I don't recall the extact dimension in my IH Service Manual but the procedure it states is to wrap a piece of masking tape around a punch the given dimension from the end of the punch and then drive the roll pin until the tape reaches squash plate surface. I will have to look up the dimension. The idea is to get the roll pin completely in the trunnion shaft.

The later hydro pumps had two roll pins on each shaft and the roll pin holes were drilled on through the back of the squash plate and you can drive the roll pins on through. Quickest way to tell if you have an early style or later style pump is to take a piece of wire and stick it down into the roll pin and see if it goes through and comes out the back.

It depends whether or not you have a early hydro pump or later hydro pump. Early hydro pumps did not have the hole for the roll pins going through the back side of the squash plate control and only have a single roll pin on each trunnion shaft. If you drive the roll pin in too far it will bottom out in the squash plate hole for the trunnion and make it difficult to remove the trunnion shafts due to the pin contacting the hole. I don't recall the extact dimension in my IH Service Manual but the procedure it states is to wrap a piece of masking tape around a punch the given dimension from the end of the punch and then drive the roll pin until the tape reaches squash plate surface. I will have to look up the dimension. The idea is to get the roll pin completely in the trunnion shaft.

The later hydro pumps had two roll pins on each shaft and the roll pin holes were drilled on through the back of the squash plate and you can drive the roll pins on through. Quickest way to tell if you have an early style or later style pump is to take a piece of wire and stick it down into the roll pin and see if it goes through and comes out the back.

Ken D.

You dint look close enough.

You dint look close enough.

rchristensen

Well-known member

- Joined

- Aug 12, 2006

- Messages

- 933

- displayname

- Richard Christensen

Jason if your not careful you can drive the pin out the back and through the case.

There are different combinations on the pins depending on early or late version, or if someone has had the hydro apart, usually I find one pin on the side with the stub shaft and two pins on the side with the trunion shaft.

Mark a punch at 15/32 like this.

Drive the pin in to the swash plate the 15/32. I usually start with the stub shaft side and just stop short of the 15/32 and then try and rotate the stub shaft. If it doesn't rotate drive the pin just a little bit and try again. The object is to just push the pin into the stub shaft, it should just fit inside the shaft if you don't drive it too far. Once the pin is inside the shaft you can rotate the shaft independently of the swash plate. Don't remove the stub shaft until you have the pin or pins out of the side with the trunion shaft.

When you drive the pins in the trunion shaft side there will probably be two. It works about the same way drive the punch in 15/32 and one pin should be in the trunion shaft and the other in the lower part of the swash plate. I stop just short and try and rotate the trunion shaft, if it doesn't rotate then just drive the pin in slightly and you should find a point where the trunion shaft will just rotate independently of the swash plate. Once you can rotate the stub shaft and trunion shaft independently of the swash plate you can remove the shafts and the swash plate.

If all else fails you will have to drive the pins all the way through the shaft and to do that you must have the swash plate rotated CCW to prevent damage to the case. I have my mounting board marked with the correct rotation on the board so I don't forget.

There are different combinations on the pins depending on early or late version, or if someone has had the hydro apart, usually I find one pin on the side with the stub shaft and two pins on the side with the trunion shaft.

Mark a punch at 15/32 like this.

Drive the pin in to the swash plate the 15/32. I usually start with the stub shaft side and just stop short of the 15/32 and then try and rotate the stub shaft. If it doesn't rotate drive the pin just a little bit and try again. The object is to just push the pin into the stub shaft, it should just fit inside the shaft if you don't drive it too far. Once the pin is inside the shaft you can rotate the shaft independently of the swash plate. Don't remove the stub shaft until you have the pin or pins out of the side with the trunion shaft.

When you drive the pins in the trunion shaft side there will probably be two. It works about the same way drive the punch in 15/32 and one pin should be in the trunion shaft and the other in the lower part of the swash plate. I stop just short and try and rotate the trunion shaft, if it doesn't rotate then just drive the pin in slightly and you should find a point where the trunion shaft will just rotate independently of the swash plate. Once you can rotate the stub shaft and trunion shaft independently of the swash plate you can remove the shafts and the swash plate.

If all else fails you will have to drive the pins all the way through the shaft and to do that you must have the swash plate rotated CCW to prevent damage to the case. I have my mounting board marked with the correct rotation on the board so I don't forget.

Lonnie, my friend, sorry to hear about your problems. My Sister-in-Law had that several years ago and needed surgery. Everything is OK now, just annual checkups. So, my friend, hang in there and all will be OK.

I see from your posting you are all set for snow. I am too, got the plow on the 149 and just got the snow thrower on the 127. That one needed a leak in the gas tank fixed first. And I got a couple of shovels ready to go, too. (They are for the wife!!) And for Vince if he would only show up when I need him.

Again take care Lonnie and its early but, Happy Thanksgiving to all. Ron

I see from your posting you are all set for snow. I am too, got the plow on the 149 and just got the snow thrower on the 127. That one needed a leak in the gas tank fixed first. And I got a couple of shovels ready to go, too. (They are for the wife!!) And for Vince if he would only show up when I need him.

Again take care Lonnie and its early but, Happy Thanksgiving to all. Ron

Here's my attempt to repair the damaged drive hub assembly. I was able to weld and fill-in the worn area and I replaced the pin in the drive shaft. Some grinding and filing but I think it shaped up pretty well.

$3.27 for the replacement pin, $4.99 for a new can of cub cadet yellow and another 30 years of service for this driveline..............Can't beat that!!!!!

$3.27 for the replacement pin, $4.99 for a new can of cub cadet yellow and another 30 years of service for this driveline..............Can't beat that!!!!!

Reggie, very nice!

Here's the latest on Killer. I moved the spring to the second hole up on the governor arm and the second hole down on the "Speed Control Bracket" and adjusted the throttle cable in the screw clamp for proper idle position. Idle is ~1200 RPM and WOT is ~3650 RPM. Close enough for now. I also attached the QA42 snowthrower and greased it up. I put the chains on topped off the air in the front tires and filled it up with fresh gas. K4K is back in the main shed and the #2 125 with Killer is in the lean-to. I plan to haul up the old 4 place horse trailer from my parent's farm and park that just off the driveway as a winter home for the #2 125. I can't bear the thought of Killer being exposed to the elements.

Let it snow, let it snow, let it snow.

Let it snow, let it snow, let it snow.

Here's the latest on Killer. I moved the spring to the second hole up on the governor arm and the second hole down on the "Speed Control Bracket" and adjusted the throttle cable in the screw clamp for proper idle position. Idle is ~1200 RPM and WOT is ~3650 RPM. Close enough for now. I also attached the QA42 snowthrower and greased it up. I put the chains on topped off the air in the front tires and filled it up with fresh gas. K4K is back in the main shed and the #2 125 with Killer is in the lean-to. I plan to haul up the old 4 place horse trailer from my parent's farm and park that just off the driveway as a winter home for the #2 125. I can't bear the thought of Killer being exposed to the elements.

prightmyer

Active member

- Joined

- Nov 8, 2005

- Messages

- 38

- displayname

- Peter A. Rightmyer

Hey Reggie, just get a driveshaft flange, rag joint "flex disc", and a driveshaft coupler. May have to drill a new hole in the driveshaft but it works awesome. I have done this mod on a few tractors. The flex disc takes the shock out of the driveline and will last a long time. Take a look at the driveshaft connection on something like a 682 and you will see the set up. I have also modified the driveline with a u-joint that came off of an S-10 steering shaft. That worked to, but you have to do a little welding. Check page 2 of the FAQ's #25. Good luck.

Richard/Ron

where do you get your gaskets for the case Ect And O rings?(for the hydro!)I was told to email the sponsors above if I dont see them listed,they may have some layin around!I HAVE NOT done this yet but will in the future when the money is a constant flow around here!!

Im just trying to get some options.

where do you get your gaskets for the case Ect And O rings?(for the hydro!)I was told to email the sponsors above if I dont see them listed,they may have some layin around!I HAVE NOT done this yet but will in the future when the money is a constant flow around here!!

Im just trying to get some options.

Well we took a little trip the other day with the semi and I think it likes it's new parking spot.

378 miles and the ole Binder dint miss a beat!

Then the snow started a little,

So I thought I would see if the 149 would like to play a little,

What, you can't see it?

378 miles and the ole Binder dint miss a beat!

Then the snow started a little,

So I thought I would see if the 149 would like to play a little,

What, you can't see it?

jmacdonald

Well-known member

Just finished reassembling my 125 this afternoon. I had the trunion bracket welded and installed new springs and guides. I put a little grease on the pivot points for the damper spring plate and speed control. They both moved freely. I changed the transmission fluid and installed a new filter, driveshaft and front and rear driveshaft couplers along with the flex coupling. I have yet to set the neutral position but it is very close. I have two questions after starting up. 1 the hydro creep seems much better it still speeds up some going down hill (no more out of control speed ups) and slows a little going up is this normal or is there something else I should check? 2. My speed control lever moves stiff now. It works ok, but is much harder than before the repair. This tractor sat in my garage unused since spring. Could it just be lubrication needed in the speed control linkage? In my manual it indicates lubrication points, but it looks like no greese fittings just wipe on the grease? Manual says remove the battery to see the linkage.

Thanks for any advise I come a long way to this point!

Thanks for any advise I come a long way to this point!

Similar threads

- Replies

- 29

- Views

- 3K

- Replies

- 49

- Views

- 3K